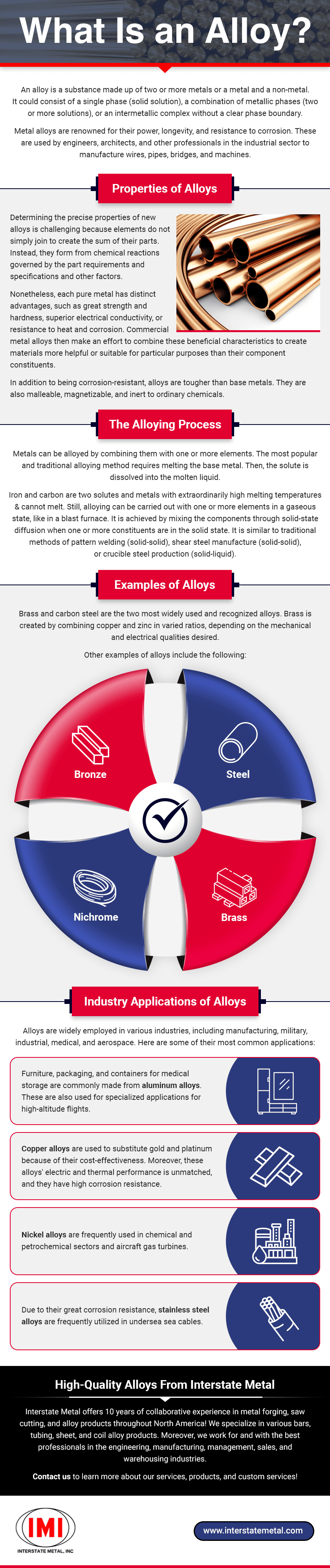

An alloy is a substance made up of two or more metals or a metal and a non-metal. It could consist of a single phase (solid solution), a combination of metallic phases (two or more solutions), or an intermetallic complex without a clear phase boundary.

Metal alloys are renowned for their power, longevity, and resistance to corrosion. These are used by engineers, architects, and other professionals in the industrial sector to manufacture wires, pipes, bridges, and machines.

Properties of Alloys

Determining the precise properties of new alloys is challenging because elements do not simply join to create the sum of their parts. Instead, they form from chemical reactions governed by the part requirements and specifications and other factors.

Nonetheless, each pure metal has distinct advantages, such as great strength and hardness, superior electrical conductivity, or resistance to heat and corrosion. Commercial metal alloys then make an effort to combine these beneficial characteristics to create materials more helpful or suitable for particular purposes than their component constituents.

In addition to being corrosion-resistant, alloys are tougher than base metals. They are also malleable, magnetizable, and inert to ordinary chemicals.

The Alloying Process

Metals can be alloyed by combining them with one or more elements. The most popular and traditional alloying method requires melting the base metal. Then, the solute is dissolved into the molten liquid.

Iron and carbon are two solutes and metals with extraordinarily high melting temperatures and cannot melt. Still, alloying can be carried out with one or more elements in a gaseous state, like in a blast furnace. It is achieved by mixing the components through solid-state diffusion when one or more constituents are in the solid state. It is similar to traditional methods of pattern welding (solid-solid), shear steel manufacture (solid-solid), or crucible steel production (solid-liquid).

Examples of Alloys

Brass and carbon steel are the two most widely used and recognized alloys. Brass is created by combining copper and zinc in varied ratios, depending on the mechanical and electrical qualities desired.

Other examples of alloys include the following:

Bronze

The earliest alloy to be discovered is bronze — mostly made of copper (85-88%), tin (12.5%–13.5%), and trace amounts of other metals, including aluminum, manganese, zinc, or nickel. This concoction is meant to enhance copper’s qualities.

Sculptures, musical instruments, medals, and many other industrial items are made of bronze.

Steel

Steel is an iron alloy that may also include manganese and has a carbon content of 1% or less. It is durable, strong, and resistant to corrosion, making it ideal for several manufacturing applications.

Steel is a common low-cost alloy used in building highways, trains, airports, bridges, skyscrapers, and other structures. In addition, it is used in major appliances and home goods.

Brass

The only distinction between bronze and brass is that bronze is a copper and tin alloy. On the other hand, brass is an alloy containing copper, zinc, lead, phosphorus, aluminum, manganese, silicon, and other elements.

Brass is used to create musical instruments, doorknobs, gears, locks, zippers, and other decorative objects. It is also suitable for a wide array of electrical and plumbing applications.

Nichrome

Nickel, chromium, and iron alloys are known as nichrome; resistance wire is routinely fabricated from this alloy. It is strong, ductile, resist electron flow, has a high melting temperature, and is resistant to oxidation. The usage of nichrome in heating elements is very common because of all these attributes.

Nichrome is employed in the production of heating elements and explosives, and fireworks.

Industry Applications of Alloys

Alloys are widely employed in various industries, including manufacturing, military, industrial, medical, and aerospace. Here are some of their most common applications:

- Furniture, packaging, and containers for medical storage are commonly made from aluminum alloys. These are also used for specialized applications for high-altitude flights.

- Copper alloys are used to substitute gold and platinum because of their cost-effectiveness. Moreover, these alloys’ electric and thermal performance is unmatched, and they have high corrosion resistance.

- Nickel alloys are frequently used in chemical and petrochemical sectors and aircraft gas turbines.

- Due to their great corrosion resistance, stainless steel alloys are frequently utilized in undersea sea cables.

High-Quality Alloys From Interstate Metal

Interstate Metal offers 10 years of collaborative experience in metal forging, saw cutting, and alloy products throughout North America! We specialize in various bars, tubing, sheet, and coil alloy products. Moreover, we work for and with the best professionals in the engineering, manufacturing, management, sales, and warehousing industries.

Contact us to learn more about our services, products, and custom services!